Equivalent operating hours (EOH) are used to determine maintenance intervals for equipment.

Typically, EOH calculations for generating facilities have been used to determine maintenance intervals, based on the assumption of primarily base-loaded operation. This line of thinking may no longer be relevant given today’s diverse operating modes. Factors, such as modified start-up profiles, over-temperature operation, increased duty cycles, low load operation, trips, unstable water chemistry, and other variables can accelerate the wear and reduce the lifespan of steam turbines.

Several original equipment manufacturers (OEMs) and industry organizations have developed long-standing formulas for determining equivalent hours. One of the most commonly used formulas is:

EOH + AOH + 25(S)

Where:

EOH = Equivalent Operating Hours

AOH = Actual Operating Hours

S = Number of Starts

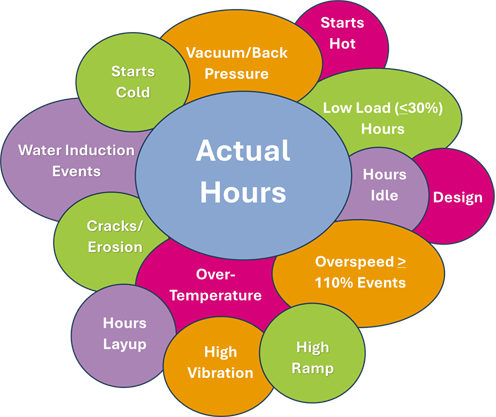

When operations deviate from their original design, maintenance issues can become more non-typical, potentially resulting in increased forced outages. Accordingly, a more comprehensive EOH approach becomes necessary. AEGIS Loss Control offers an enhanced EOH formula that incorporates additional variables for consideration:

EOH = AOH + 25(S) + Variables

EOH Variables

There are several factors to consider beyond just operating hours and starts as shown in the above diagram.

Understanding EOH is essential for those involved in the maintenance and operation of steam turbines. It is particularly beneficial for maintenance engineers, system operators and plant managers looking to optimize their equipment's lifespan and performance in line with evolving operational challenges.

For more information on how you can determine equivalent operating hours, you can read the AEGIS Loss Control white paper Steam Turbine Equivalent Operating Hours (EOH) – Calculation and Maintenance Interval Considerations.

If you have any questions, please reach out to Timothy Maker, Machinery Supervisor in Loss Control via e-mail.

About Quick Tips

We send Quick Tips to the managers and operational professionals on our e-mail list, but please feel free to forward this to others in your organization who you feel may benefit. We would be pleased to add their names to the distribution list. Just let us know at quicktips@aegislimited.com.

The content of this Quick Tip is illustrative in nature and does not purport to describe all potential hazards or to indicate that no hazards exist. This paper is not a substitute for expert advice. Neither the author nor AEGIS Insurance Services, Inc. endorses or guarantees that any particular practice or procedure is safe in all cases or meets any code or regulatory requirement. This paper is provided without warranties of any kind.